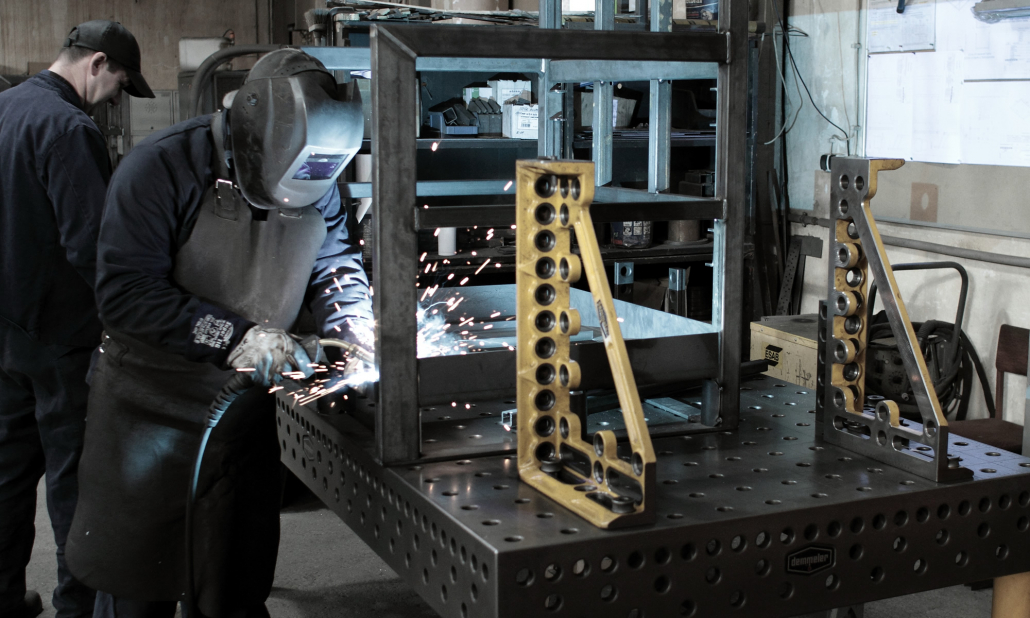

A well-coordinated team of craftsmen

The strengths of our team are evident in conventional metalworking. With full commitment and many years of experience, we fulfil our customers’ expectations. We mould metal into a solution.

Welding

The hand-welded seams produced by our trained and certified welders are characterised by particular precision and quality. We weld component groups stably and durably using various welding processes (MIG, MAG, TIG).

Turning, drilling, milling

We are experienced metalworkers and utilise conventional metal cutting techniques. Experienced craftsmen with their knowledge of machines and materials are particularly useful for customisation and smaller series. In combination with automated production processes, we can optimise the manufacturing process and reduce unit costs.

Punching and edging

Punching is economically superior to laser cutting for the production of openings and cut-outs in sheet metal in large quantities. We produce the upper and lower tools for the punching process in-house.

We bend sheet metal on our CNC-controlled press brake with a pressing force of up to 230 tonnes over a length of 3 metres.

Deburring and grinding

We prepare surfaces to ensure safe handling, further processing or coating. Larger and more complex workpieces are deburred and sanded manually using hand tools.