Production in steel, stainless steel and aluminium

Manufacturing

We produce with and for industrial and commercial companies. Our production facility is designed for the manufacture of small, medium and large series in batch sizes of 50, 100 and 500 pieces per production cycle. We process steel, stainless steel and aluminium into complete (sub)assemblies or semi-finished products.

We are particularly competitive in the realisation of labour-intensive products with a high degree of individualisation.

Reproducible quality

Automation

and CNC manufacturing

CNC lasers, 3D lasers, welding robots, CNC saws – more and more of our production machines are digitally controlled. This allows us to offer you a good price-performance ratio and a high degree of controlled, repeatable quality.

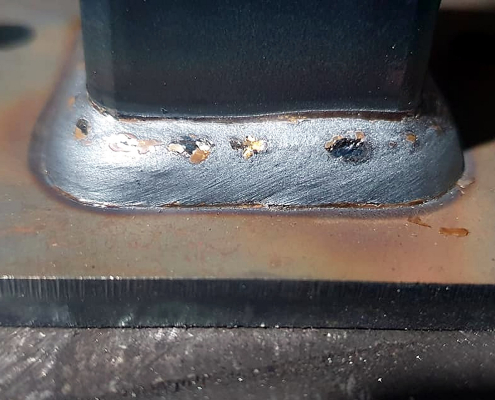

Quality in craftsmanship

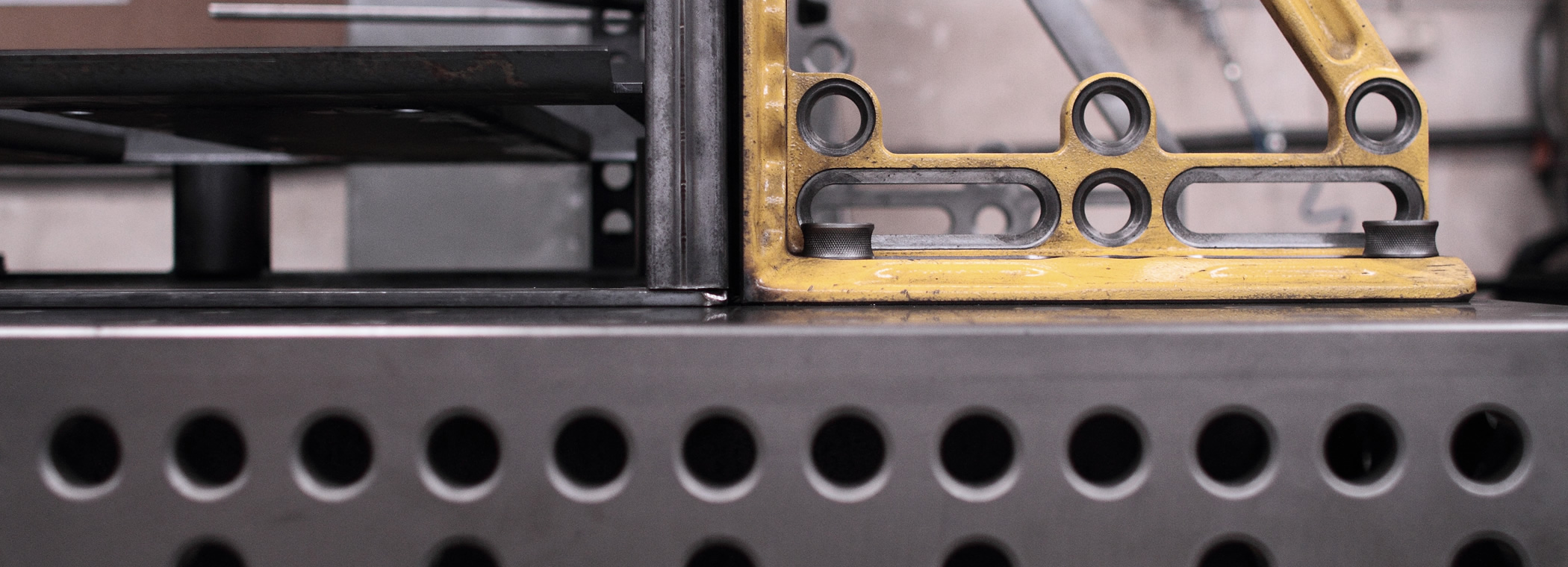

Steel construction and

metalworking

Our automated production goes hand in hand with conventional metalworking methods. Our team’s craftsmanship is the key to the quality of the finished products.

Our aspiration

Precision

When rigid metal fits together with such precision and form-fit, it is a particular pleasure for us.

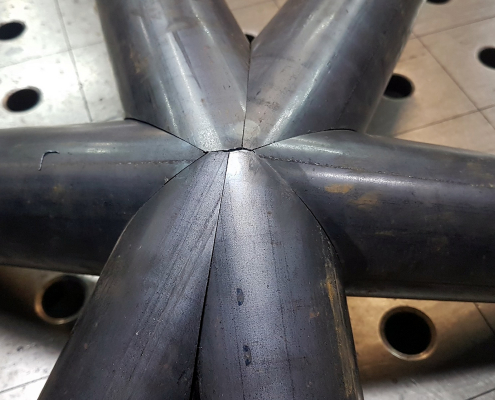

Processing

The quality of our weld seams is often rated as particularly good. We are proud of this.

Meeting deadlines

Coordinating our capacities on schedule is a task that we set ourselves and work on.

Overview of our production services

- CNC laser cutting

- 3D laser for profiles and tubes

- CNC metal saw

- CNC welding robot

- Welding (MIG-MAG)

- Resistance welding

- Deburring, grinding

- Edging, sawing, bending, turning, milling, drilling

Further services via our external partners

- Painting, powder coating

- Hot-dip galvanising

- CNC punching

- Sandblasting